CATALPA Project

Low-temperature, electrified CO₂ capture

Project coordinated by Université de Pau et des pays de l’Adour

Duration of 4 years

2,65 millions euros of budget

5 doctoral students, 54 months of post-doctoral research, 5 patents expected and 15 publications in international journals expected

Context and challenges

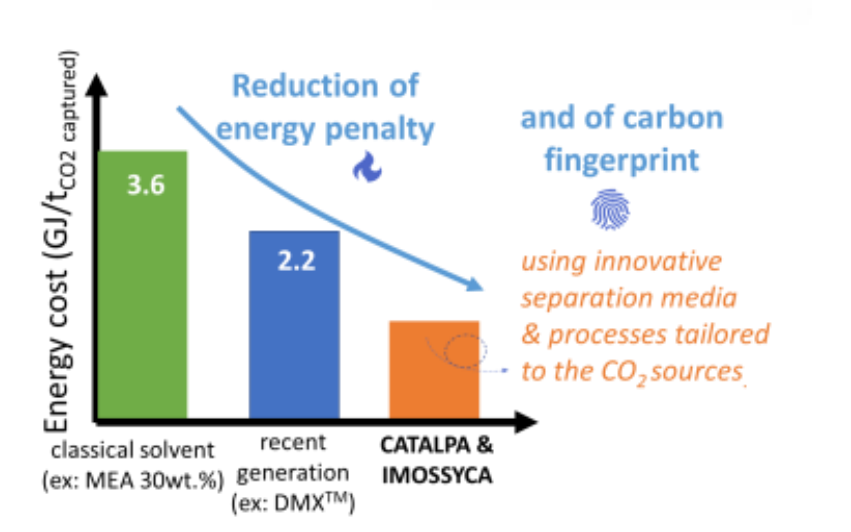

CO₂ capture is a key solution for decarbonising industries, particularly those whose emissions are difficult to reduce and concentrated. However, the costs, performance and energy penalty of CO₂ capture processes are hindering their deployment. It is also necessary to adapt the separation medium and capture process to the type and quantity of waste gases to be treated.

Scientific objectives

The aim of the CATALPA project is to investigate new ways of reducing the energy and carbon footprint of CO₂ capture processes. The main energy penalty of CO₂ capture is the regeneration of the CO₂ separation medium, whether solid or liquid. This penalty often takes the form of thermal energy, which often involves an increase in CO₂ production. Even if this CO₂ is captured, it increases the amount of CO₂ transported and stored, which also increases the cost of CO₂ avoidance.

Two different methods will be explored in this project to reduce the energy penalty:

- The integration of decarbonised energy to support the dedicated use of thermal energy and reduce it.

- The reduction of specific energy regeneration based on an innovative separation medium.

The first method involves striking the right balance between capacity, selectivity and specific energy regeneration, while ensuring that the proposed solution meets environmental criteria relating to the volatility, toxicity and degradability of the products.

The second method involves efficiently supplying carbon-free energy to the separation environment in order to replace or reduce the use of high-temperature thermal energy. The aim is to use less thermal energy or reduce its temperature to a level that allows the use of low temperatures, i.e. below 100 degrees, in order to reduce energy costs and enable the use of energy from waste.

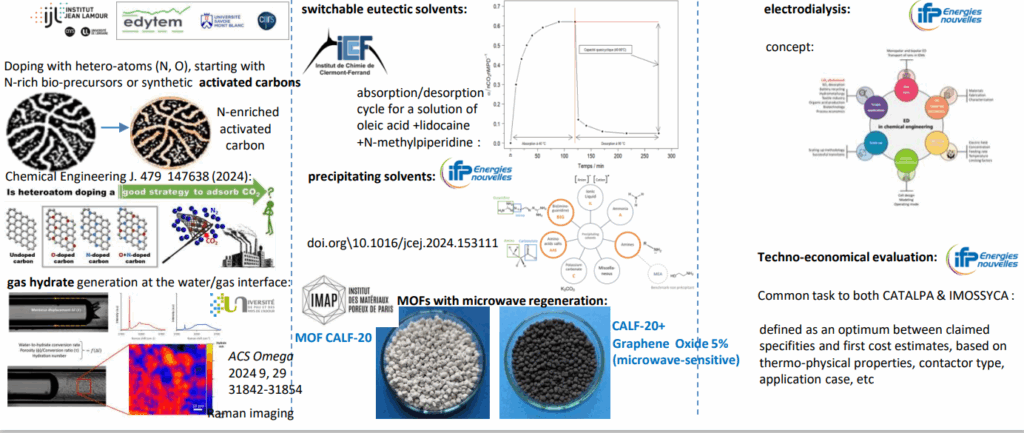

The aim of this project is to propose innovative separation media and processes involving gas hydrates, organometallic framework materials, adjusted, modified or activated solvents and carbons, as well as deep eutectic solvents and precipitation solvents. Some of these processes, such as sorbent regeneration or electrodialysis, enable the use of carbon-free electricity and thus reduce the carbon footprint.

Innovative separation media for low-carbon CO₂ capture processes, management of alternative energy activation for CO₂ capture process regeneration, techno-economic evaluation of innovative solutions compared to reference CO₂ capture processes and expected gains.

The consortium

IFPEN, Laboratoire des Fluides Complexes et leurs Réservoirs LFCR (CNRS – Université de Pau et des Pays de l’Adour/Total Energies), Institut des Matériaux Poreux de Paris IMAP (CNRS, ENS, SPCI), Laboratoire Environnement Dynamique Territoires Montagnes EDYTEM (CNRS, Université Savoie Mont Blanc), Institut de Chimie de Clermont Ferrand ICCF (CNRS, Université Clermont Auvergne)

Interim results

More projects