DCARBO Project

Real-time monitoring

Project coordinated by IFP Energies nouvelles

Duration of 5 years

1,58 millions euros of budget

2 theses et 1 internship

Context and challenges

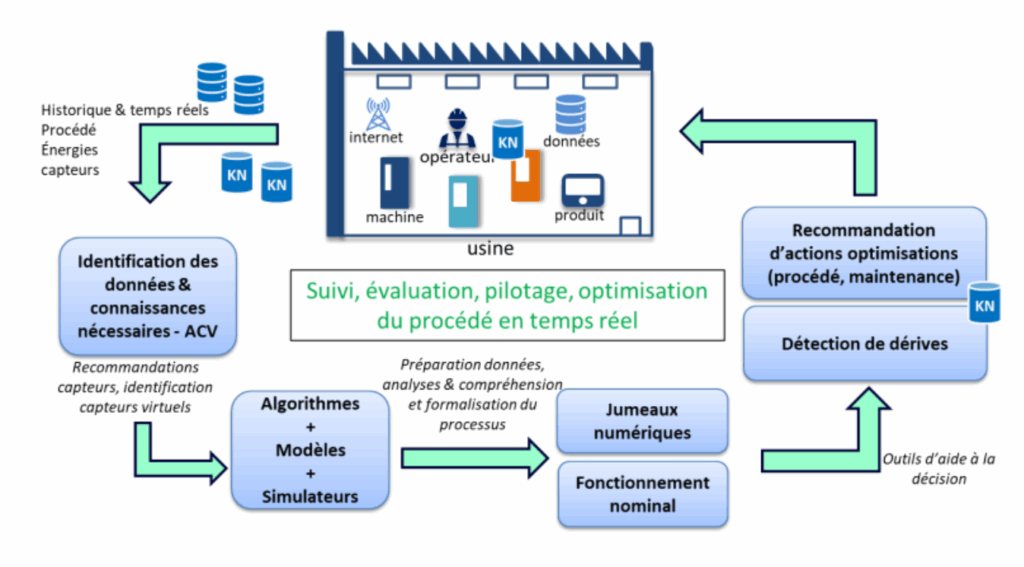

Decarbonising industry requires better control and more detailed knowledge of CO₂ emissions from production systems. Installing sensors in strategic locations and managing production data in real time provides relevant information that enables dynamic analysis of CO₂ emissions with greater accuracy than current asynchronous approaches.

Scientific objectives

The challenge is to define, for different types of production systems, the appropriate structure for acquiring and collecting relevant data, as well as for the associated decision-making tools for decarbonisation.

The aim is to propose suitable artificial intelligence and algorithm models for each decision-making level, to test and compare different models and algorithms, and to establish a methodology for implementing new approaches in industrial contexts. The originality of this research lies in the coupling of different types of AI and their application to real-time monitoring and control of industrial processes, in order to promote effective decarbonisation of industries.

The main challenges of this project will be related to finding the right level of process information/instrumentation and the complexity of managing simulations for short-term and real-time decision-making.

Establish a methodology for monitoring indicators related to one or more production units, reflecting the environmental impact of that unit based on its various components: energy consumption, resources and emissions related to water, air and soil.

Three types of processes will be concerned: discrete processes (manufacturing industries, microelectronics), continuous processes (cement works, local distribution operators for heating networks) and data centres and storage facilities for digital industries. It will be important to identify the differences between these types of processes and their impact on the method to be developed. A link will be made with the targeted dynamic LCA project.

TRL 4 at the end of the project.

Expected outcomes and impacts

A generic approach enabling industries to identify key parameters for monitoring and analysing their CO2eq emissions, determining the data acquisition tools needed to collect these parameters, and implementing the relevant tools for detecting deviations and recommending actions to reduce emissions.

Methodology and tools that will enable industry to develop decarbonisation scenarios aimed at achieving France’s energy and climate objectives by 2050.

The consortium

Submitted publications

“Decarbonization in Manufacturing: A Systematic Review for Life Cycle Assessment with Sensor Data Integration”, Quintero-Herrera, S; Evrard, D., 32nd CIRP LCE, 07 au 09 avril 2025.

“Energy-Aware Cloud Task Scheduling: A comprehensive Dialectical Approach” , A. Hattay, E. Gascard, Z. Yahouni, F.-M. Ngole Mboula, 17th IEEE Utility and Cloud Computing conference,16 au 19 décembre 2024

More projects