ECOCHEM Project

Efficient catalysts and processes

Project coordinated by Université de Poitiers

Duration of 5 years

5,9 millions euros of budget

5 patents, 5 to 7 proposals for new products and solvents, 5 to 7 proposals for technological building blocks or proof of concepts, software and control tools.

Context and challenges

The chemical industry lies at the heart of our societies, as it is used to produce a wide range of goods essential to our development. However, the impact of human activity on the planet (water availability, biodiversity loss, climate change) and the exponential growth of the global population have reshuffled the deck: chemistry must now solve a complex equation—how to produce more and better with less.

In this context, catalysis plays a crucial role, not only in better controlling the selectivity of desired products (towards a zero-waste objective) but also in lowering the energy barriers of reactions, thereby reducing overall CO2 emissions within chemical processes.

Scientific objectives

The ECOCHEM project aims to investigate innovative catalytic technologies for the synthesis of fine chemicals from inexpensive and industrially relevant feedstocks such as N₂, NH₃, light alkenes, light alcohols, and others, through eco-efficient processes.

By eco-efficient processes, we refer to processes or reactions that emit less CO₂ (i.e., better energy utilization, simplified downstream processing, cascade reactions, intensified processes/reactions, reduced waste, catalysis, etc.).

In this context, the project will have to address two scientific challenges:

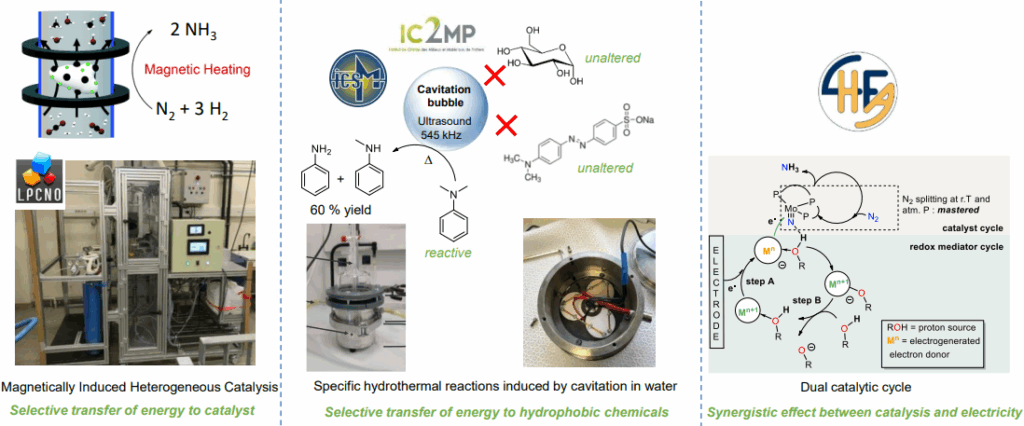

- The design of catalytic systems (both homogeneous and heterogeneous) based on sustainable and disruptive technologies, as well as their smart implementation in catalytic processes. The main challenges concern catalyst recyclability, continuous-flow reactor operation, and the hybridization of reaction cascades.

- The development of catalytic reactions at low temperatures. The coupling of catalysis with auxiliary promotion tools (ultrasonic waves, electric and magnetic fields, light), which has recently emerged as assisted catalysis, will be explored. The main challenge will be to confine these physical effects on a catalyst surface so that a synergistic effect can occur. To optimize the energy consumption of these technologies, process intensification will be pursued (from batch to continuous, microfluidics, etc.).

Key highlights

National impact

The project is linked in a complementary way to various national initiatives. For example, IC2MP, LGC, and ISCR are working jointly within the research federation INCREASE, hosted by CNRS, a public-private network dedicated to sustainable chemistry. A direct connection is thus established with several chemical companies, particularly in the field of fine chemistry (SOLVAY, PENNAKEM, ARD, L’ORÉAL, GREENTECH, FCBA). These companies should be considered potential candidates for the valorization and exploitation of the results generated within this project.

AXELERA, the French cluster bringing together 400 industrial and academic stakeholders in the fields of chemistry and the environment, is also expected to be involved in the valorization of the project’s outcomes, by promoting their dissemination to chemical companies. The project will also benefit from the national platforms REALCAT, AXELONE, and MEPI.

National impact

In Europe, many chemical companies are involved in the production of fine chemicals, including major industrial players such as AKZO NOBEL, BASF, BAYER, SOLVAY, ARKEMA, ADISSEO, ELKEM, SEQENS, INEOS, and CLARIANT. The development of advanced technologies for the conversion of chemical substances through more eco-efficient methods has been identified as a key priority in industrial roadmaps. The expected impacts include reduced industrial production costs through higher reaction yields, decreased raw material and energy consumption, as well as a lower environmental footprint at industrial sites.

International impact

The project is connected to the international scene through the International Symposium on Green Chemistry (ISGC). Cooperation with other countries, in particular Leuven (Belgium, catalytic design), Aachen (Germany, homogeneous catalysis), and Valencia (Spain, fine chemistry), will be strengthened.

Expected results

A reduction in CO₂ emissions is expected in the following areas: (1) detergents, paints, and cosmetics; (2) polymers (packaging, construction, automotive, electronics); and (3) solvents.

The structuring of a national multidisciplinary community on catalyst design and assisted catalysis, the integration of catalysts into catalytic processes, and the multi-scale approach.

Training of students better equipped to meet the future challenges facing the chemical industry.

Provision of scientific expertise to chemical companies, which are currently in high demand for innovative and environmentally friendly technologies.

The consortium

IC2MP (CNRS, Université de Poitiers), IFPEN, IRCELYON (CNRS, Université de Lyon), UCCS (CNRS, Université de Lille), LGC (CNRS, Université de Toulouse, Toulouse INP), LHFA (CNRS, Université de Toulouse), ICSM (CEA, CNRS, Université de Montpellier), ICPEES (CNRS, Université de Strasbourg), ISCR (CNRS, Université de Rennes), LPCNO (CNRS, Université de Toulouse, INSA Toulouse), CP2M (CNRS, Université de Lyon).

More projects