IMOSYCCA Project

Modular CO₂ capture systems

Project coordinated by IFP Energies nouvelles

Duration of 6.5 years

7,5 millions euros of budget

8 theses and 4 post-docs

Scientific objectives

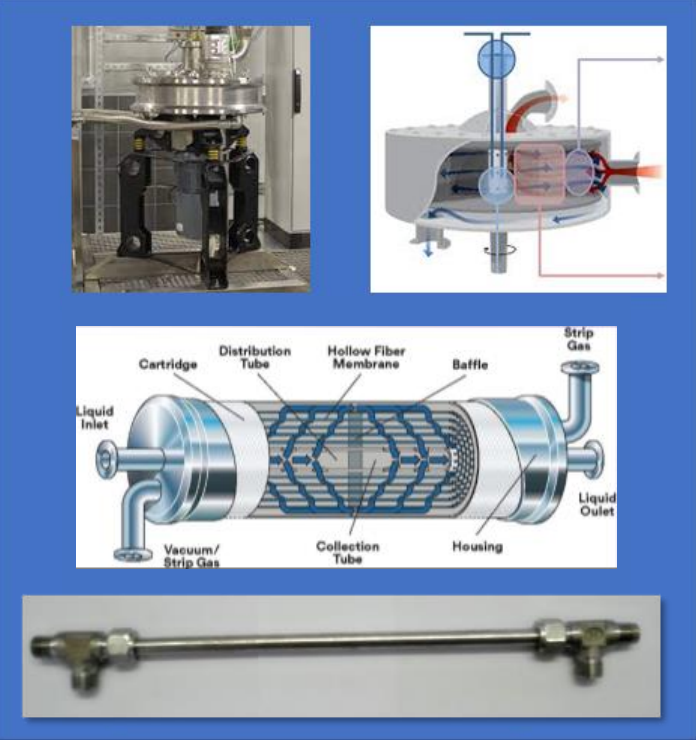

The aim of the IMOSYCCA project is to design small, easy-to-use CO₂ capture units that can be used by end consumers who are unfamiliar with the use of chemicals. This will be made possible by the simultaneous design of new green and non-toxic absorption solvents and the use of innovative absorption technologies, i.e. membrane contactors or rotating packed beds (RPB). The aim is to achieve an intensified, environmentally friendly process that takes into account energy penalties and environmental impact and includes solvent regeneration. The membrane contactors will be equipped with a composite membrane with a dense surface layer that avoids the limitations associated with membrane humidification.

The challenges are as follows :

Propose a modular process design using intensified technologies such as hollow fibre membrane modules or a rotating packed bed.

Conceptualise bio-based solvents with low toxicity and good operability for use by non-specialists, with low environmental impact (volatility, product degradation, land use, etc.).

Conceptualise an energy-efficient process with a limited energy footprint (quantity and quality of energy).

Design of new solvents, new membranes for membrane contactors, modelling and testing of membrane contactors, ageing and degradation of separation media, modelling, testing and design of RPB dedicated to CCS, integrated modular unit for CO₂ capture

The TRL level of the project is governed by the TRL of the solvent. The project will start at TRL 1.

Membrane and RPB technologies start at TRL 2, and the integrated process should reach TRL 4 by the end of the project.

Expected outcomes: 4 to 6 patents, 3 to 5 environmentally friendly solvents, at least two proofs of concept (membranes and RPB), process simulation tools, 8 PhD students, 4 postdocs (78 months), between 20 and 30 publications.

The commercialisation of the products should generate business for membrane and module manufacturers (e.g. Polymen), technology integrators and licensors such as Axens and Arrol, as well as end users of CO₂ from fossil fuel consumption or as a result of their processes (e.g. methanisation).

The consortium

Laboratoire de Génie Chimique LGC (CNRS, Université de Toulouse, Toulouse INP), Laboratoire Réactions et Génie des Procédés LRGP (CNRS, Université de Lorraine) LCA (INRAe, Toulouse INP), IFPEN, Laboratoire de Chimie-Physique Macromoléculaire LPCM (CNRS, Université de Lorraine)

More projects