OXY-3C Project

CO2 capture through oxy-combustion

Project coordinated by the CNRS

5-year term

2,88 millions euros of budget

8 doctoral students and 4 post-doctoral researchers expected

Background and challenges

Carbon capture, utilisation and storage (CCUS) is one of the key pillars of the scenario for reducing anthropogenic CO2 emissions.

Scientific objectives

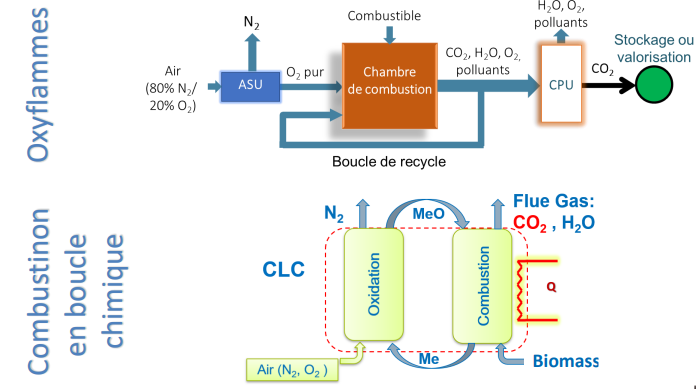

For high-temperature heat production in industry, the OXY3C project aims to optimise (efficiency, impact) oxy-combustion processes for CO2 capture at source via chemical looping combustion (CLC) of biomass or natural gas (NG) and biogas oxy-flames. It thus offers solutions tailored to negative emissions by considering biofuels and bringing together a community specialising in oxy-combustion.

With regard to oxy-fuel applications, the project will intensify multiphysical analysis based on advanced laser diagnostics for in situ measurements under complex conditions, improve kinetic models of oxy-fuel flames with high CO₂ and water dilution, and develop high-fidelity numerical simulation while understanding the subsequent transfer to industry.

Both approaches will be tested using two different methods:

- The use of cryogenic separation of oxygen by electricity (ASU) or membranes or combustion gases from electrolysers in industry.

- Avoiding the energy consumption of ASUs by using metal oxides as oxygen carriers in the oxy-combustion process.

Expected synergies: PEPR work on decarbonising heat production (via hydrogen, ammonia, biomass), emissions control (in particular the development of ultra-low NOx processes, e-fuel production via CO₂ recovery, scaling issues, specific instrumentation.

The consortium

CORIA (CNRS, Université de Rouen Normandie, INSA Rouen Normandie), EM2C (CNRS, CentraleSupélec, Université Paris-Saclay), LRGP (CNRS, Université de Lorraine), IMFT (CNRS, Toulouse INP, Université de Toulouse), MSME (CNRS, Université Gustave Eiffel), LGRE (Université de Haute-Alsace), PC2A (CNRS, Université de Lille), IFPEN

Initial search results

Federation of 42 scientists, including 9 PhD students and 1 post-doctoral researcher recruited via OXY3C (including 2 co-funding projects)

Initiation of numerical simulation work for flames and fluidised beds

Exchange of a benchmark for kinetic models

Development of experimental devices specific to oxy-combustion conditions and biomass

Development of chemical kinetics codes for biomass and CO₂/H₂O atmospheres, identification of initial discrepancies with popular kinetic codes (NG combustion)

Expected results

Original databases specific to oxy-combustion (CO₂/H₂O atmosphere)

Numerical simulation codes transferable to industry (YALES2), Neptune-cfd flames or CLC

Biomass pyrolysis and char gasification

Kinetic pathways for biomass in oxy-combustion

Coupled combustion solver for swirled and reactive flows with radiative heat transfer

Original developments in numerical simulation through the complementary use of micro (DNS), meso (LES) and macro (RANS) approaches for the development of predictive tools for a CLC unit

More projects